Home

See on Youtube the first image scanning by a plastic image sensor :

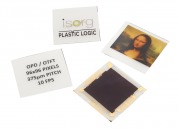

See on Youtube the first image scanning by a plastic image sensor :http://www.youtube.com/watch?v=iLWuh0uwSh0 ISORG and Plastic Logic have co-developed the first conformable organic image sensor on plastic, with the potential to revolutionise weight/power trade-offs and optical design parameters for any systems with a digital imaging element. First presentation will be publicly unveiled at Printed Electronics USA 2013 in Santa Clara on november 20th-21th 2013. The collaboration is based on the deposition of organic printed photodetectors (OPD), pioneered by ISORG, onto a plastic organic thin-film transistor (OTFT) backplane, developed by the technology leader, Plastic Logic, to create a flexible sensor with a 4×4 cm active area, 375um pitch (175um pixel size with 200um spacing) and 94 x 95 = 8 930 pixel resolution. The backplane design, production process and materials were optimised for the application by Plastic Logic to meet ISORG’s requirements. The result, a flexible, transmissive backplane, represents a significant breakthrough in the manufacture of new large area image sensors and demonstrates the potential use of Plastic Logic’s unique flexible transistor technology to also move beyond plastic displays. Combined with ISORG’s unique organic photodetector technology, it opens up the possibilities for a range of new applications, based around digital image sensing, including smart packaging and sensors for medical equipment and biomedical diagnostics, security and mobile commerce (user identification by fingerprint scanning), environmental, industrial, scanning surfaces and 3D interactive user interfaces for consumer electronics (printers, smartphones, tablets, etc.). |

|

ISORG a développé des interfaces utilisateurs / interfaces homme-machine innovantes basées sur ses capteurs optiques en électronique organique imprimée, les Magic Twist et Magic Slider. Grâce aux photodétecteurs de grande surface positionnés sous la surface, les surfaces de verre et de plastique sont transformées en surfaces interactives capable de détection de proximité de la main et de détection de mouvements. Ces surfaces peuvent être utilisées comme surfaces tactiles avec des usages robustes (opérant avec de la graisse et de l’eau sur la surface, opération avec des gants), en particulier pour les produits électroménagers et applications industrielles. Elles peuvent également être utilisées sans contact par détection à quelques centimètres de la surface (par détection de lumière infra-rouge réfléchie par la main). Cette interaction sans contact permet la création d’objets à très forte innovation et haute valeur ajoutée pour le marché de l’électroménager et des jouets. Vidéos en ligne sur Youtube : Magic Twist : https://www.youtube.com/watch?v=TEplkxpFT8A https://www.youtube.com/watch?v=gaFZYa8OrsI Magic Slider : https://www.youtube.com/watch?v=cDzsRDx34U4 https://www.youtube.com/watch?v=3WZ2uCrStXg |

A new prototype demonstrate the potential of conformable plastic-based image sensors.

A new prototype demonstrate the potential of conformable plastic-based image sensors. Flexible image sensor A recently unveiled proof-of-concept device indicate the strides being made towards flexible plastic-based image sensors, and the potential advantages they may have over their inorganic counterparts. The device developed by Plastic Logic of the UK and France’s ISORG, was on show at the LOPE-C 2013 printed electronics conference held in Germany in June 2013. On the threshold The Anglo-French sensor is said to be the first conformable organic image sensor of its type, potentially allowing more favorable power-to-weight trade-offs and novel optical design parameters for any systems with a digital imaging element. “This is the first time an organic thin-cell transistor backplane has been combined with a organic photodiode layer which is printed over the plastic substrate,” confirmed Ian Reid of Plastic Logic to Optics.org. “Plastic Logic manufactured the plastic organic thin-film transistor backplane, which was then combined with ISORG’s organic photodetector (OPD) technology. Some integration work was involved, but both processes are fundamentally mature and established by the respective companies.” The result was a flexible sensor with a 4 x 4 cm active area; a pitch of 375 microns, with 175 microns pixel size and 200 microns spacing; and a 94 x 95 pixel grid. “This is a proof-of-concept demonstrator and was designed as such, so we did not push the manufacturing process or the sensor performance to its absolute limit,” noted Reid. “The pixel resolution, which is determined by the backplane, equates to 60 pixels per inch (ppi); not spectacular, but chosen to simplify the testing and characterization task at this stage.” Although the developers have set no target resolution for any final product, the high-resolution processing developed by Plastic Logic for the manufacture of backplanes in electrophoretic displays has comfortably achieved densities of 150 to 225 ppi, so steps towards that figure seem readily foreseeable. Both the backplane and the OPD layer are manufactured using printing operations at ambient temperature, potentially leading to substantial cost-efficiencies compared to the manufacturing processes involved in traditional inorganic components. A printing operation could also enable distributed sensor arrays over larger areas than can be achieved by silicon-based processes, avoiding the limits imposed by wafer size and fabrication technology. The flexible nature of the sensors should bring its own advantages, lending itself to non-planar sensor arrays following curved or distorted paths, and opening up an extra design dimension for engineers. A further advantage could be the greater spectral range commonly shown by OPD components, and Reid envisages imaging systems able to employ the same component type for near-IR and visible sensing. “We have known for some time that our flexible plastic technology is usable not just in backplanes for driving displays, but for other types of applications too,” he said. “Having industrialized a process successfully for driving electrophoretic displays, it’s natural to look at where we can take the technology. We are on the threshold of something very exciting in the flexible electronics area, and the design community is starting to think about what they can do with it.” www.optics.org Tim Hayes is a contributing editor at Optics.org |

|

Printed Electronics USA, Santa Clara, CA Laurent Jamet from ISORG presented the results of their efforts to print near-IR opto-detectors on various substrates. The capability to place optical detectors on a substrate allows new modes of sensing and interactivity in many applications. Photodetectors with near linear response and low dark current are possible with printable materials. An active matrix of detectors can resolve at resolutions down to 50 microns, and can scale to larger image sizes. The sensor arrays are placed in a 32 x 38cm area in a sheet-to-sheet process. The process can use either glass or plastic substrates. For large area sensing, the image resolution can be increased up to 1cm and the functions can be set for larger object detection. The resulting flexible electronics can be placed on non-planar surfaces. This flexible circuitry needs mechanical integration to achieve thin, light, and customizable optical sensing. Some specialized applications include 3-D detection over a 0-50cm range, large area detection, and non-optical sensing. Interactive surfaces in various configurations are possible. Some functions include point of sales terminals, interactive posters, smart phones, and man-machine interfaces. Other areas like toys, educational environments, automotive, and consumer electronics can all use this technology, as well as some versions of smart packaging. Potentially, this material can be used to replace a computer mouse, but the resolution will call for a sensor that is over 6-inches in diameter. The detectors can be coupled with IR emitters to from an active sensor that can detect gross and medium coarseness motions. One version of the sensor array can detect motions of a whole hand, or individual fingers, but could not detect a single finger motion December 6, 2012 Media & Entertainment Technology http://mandetech.com/2012/12/20/printed-opto-detectors/ |

| Isorg and Sumitomo Chemical Announce Partnership to Develop Organic Photodetectors |

|

Grenoble, France, and Tokyo, Japan, July 1, 2019 Isorg, a pioneer in organic photodetectors (OPDs) and large-area image sensors, and Sumitomo Chemical, a global leader in OPD materials production and other fields, today announced their agreement to develop new OPD products for use as smartphone fingerprint sensors and hybrid organicCMOS image sensors. This agreement expands the existing collaboration between Sumitomo Chemical and Isorg that began in 2013. Isorg will license its technology processes to its OEMs, while Sumitomo Chemical will manufacture the dedicated organic semiconductor material, as well as support Isorg in terms of production technology and marketing. This collaboration aims to provide OEMs with materials and technology processing solutions that will enable them to bring to market products using high-performance, high-quality fingerprint and CMOS image sensors. The fingerprint sensors can be incorporated beneath the entirety of a smartphone display, allowing fingerprint recognition from any point or position on that display. The hybrid organic CMOS image sensors are intended for use in cameras, including those designed for near infrared capabilities. Sumitomo Chemical and Isorg anticipate that these sensors will meet the performance and quality standards necessary for application in the security, automotive, diagnostics and consumer electronics markets. Partnering with Isorg will allow us to fill a void in the market for difficult-to-manufacture, but affordable, full-size fingerprint and CMOS image sensors that are suitable for demanding applications in smartphone displays and hybrid visible and near infrared cameras, said Hiroshi Ueda, Executive Vice President at Sumitomo Chemical. Sumitomo Chemical is leveraging its materials platform to seize new opportunities for growth in the imager arena. Isorg is honored to collaborate with Sumitomo Chemical in providing OEMs with what we believe will be the leading solution for fingerprint sensors and hybrid organic CMOS image cameras, and which offer significant performance advantages, said Jean-Yves Gomez, CEO and co-founder of Isorg. With the strong backing of Sumitomo Chemical, and its industrial leadership, global footprint and drive for excellence, Isorgs customers will have added assurances in our ability to deliver quality products. We look forward to engaging with customers on the designs and applications of these products. Going forward, Sumitomo Chemical and Isorg will work jointly on commercialization of the products to promptly meet the needs of customers. About Sumitomo Chemical Company LimitedHeadquartered in Tokyo, Japan, Sumitomo Chemical is one of Japans leading chemical companies. It offers a diverse range of products globally in the fields of petrochemicals, energy and functional materials, IT-related chemicals and materials, health and crop science products, and pharmaceuticals. The companys consolidated sales revenue for fiscal year 2018 was JPY 2.3 trillion and number of employee is about 33,000 as of March 31, 2019. For additional information, visit the companys website at https://www.sumitomo-chem.co.jp/english/ About IsorgIsorg is a pioneer in organic and printed electronics for large area photo-detectors and image sensors. It offers a new generation of high-performance imagers with 3D product integration capability that can recognize any shape or form factor. Its flexible image sensors have application in medical devices, ID security and access control, IoT and consumer electronics. It developed the first large-sized high-resolution (500 dpi) flexible plastic fingerprint sensor for biometric security and other applications. Created in 2010 and partnering with CEA-Liten, a leading French innovation center for new energy technologies and nanomaterials, Isorg achieved a Series B fundraising round amounting to €8M took place in 2014, followed by a €24M fundraising round in 2018. For additional information, visit the companys website at |